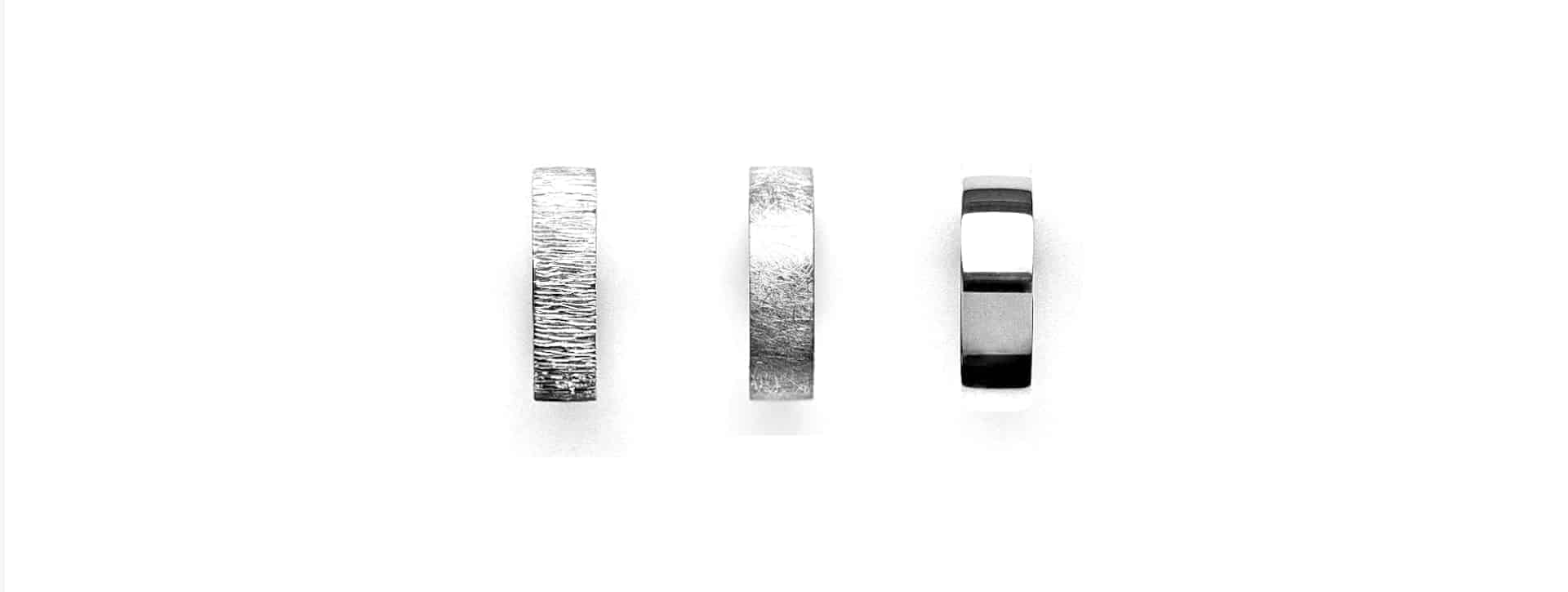

The surface gives the piece of jewelery its final appearance. Have your rings provided with fascinating structures and surface patterns to give them a very special look.

A special look

The final surface treatment lets the metal color (alloy), the ring profile and the stones of your ring appear again in a completely new light. Do you like it classic glossy or do you prefer a matt finish? Let yourself be inspired by our surface types: every wedding ring and every profile is available with a wide variety of surfaces.

|

PolishedThe most common surface, classic and traditional, especially for gold rings. The high-gloss polish makes the precious metal completely smooth and shiny - it makes the color shine. By mirroring the surroundings, scratches are initially less perceived due to the high level of reflection and the wedding rings look classy even after a long period of wear. Small gemstones can, however, lose their effectiveness with this radiance. |

|

Fine mattRadial matting along the ring is also very popular and is chosen most frequently in addition to classic polishing. The matting in one direction allows the color of the precious metal and gemstones to come into their own. The longitudinal matting appears gentle, natural, harmonious, reserved, calm and soft. In the case of longitudinal matt, it is important to note that the surface changes over time to a polished look due to the signs of wear, but it can be restored quite easily. |

|

StrichmattSimilar to Feinmatt, only that a somewhat coarser and therefore very interesting appearance is achieved here. |

|

QuermattMatting across the ring band is also very much in demand. Due to the matt finish, the color of the precious metal comes into its own better, but it appears a bit harder and makes the ring appear more voluminous. With Quermatt, too, it should be noted that the surface changes more and more to a polished look over time due to the signs of wear. |

|

Sand mattA strong, evenly matt ring surface, which is evenly covered with tiny dots, resulting in a calm, silk matt surface. This surface allows the different alloy colors to come into their own, especially with multi-colored rings, looks particularly elegant and allows even the smallest diamonds to come into their own. Sand matt is available in different "degrees of fineness" - the finer the "sand degree", the finer the matt finish, and vice versa. As with all matt finishes, it should be noted here that the surface changes more and more to a polished look over time due to the signs of wear. |

|

Ice mattThis surface is very resistant and hardly changes due to signs of wear. With this surface, the structure is applied to the wedding rings using diamond files and sandpaper in circular movements. The result is an unstructured scratch that looks like numerous skate tracks running over each other on an ice surface. Together with polished surfaces, this ring surface is enjoying increasing popularity. Small gemstones are almost invisible on ice-matt wedding rings, this surface lives on its structure alone. |

|

Crystal mattSimilar to ice matt, only that a coarser grain is used here. This creates a more distinctive appearance compared to the Eismatt. |

|

Sponge matThe surface is processed with a scotch mat. This appearance is created by the circular movements. The wearing properties are similar to those of the fine matt. |

|

SchlagmattAn increasingly popular alternative to Sandmatt, as this surface is somewhat more resistant. A fine structure is hammered out with a special hammer and then matted. Hammering in different strengths can make the appearance of this matt finish weaker or stronger. |

|

BarkCoarse milling, which is created in detailed manual work. The surface is then matted by means of brushing. This ring surface has a very individual character and is very robust. |

|

Coarse hammer blowThis coarsely hammered surface is also lovingly handcrafted. Here, with the rounded surface of a chasing hammer, many small round indentations are knocked into the ring. Rings with such a surface can usually be found in a polished state and have an extraordinary effect, which is particularly effective with wide rings. |

|

Fine hammer blowSimilar to the coarse hammer blow, only that the surface is hammered a little finer. This creates a unique, filigree structure that elegantly refracts the light. |

|

Satin finishSimilar to a rough transverse matt, a matt finish across the ring band. This matt finish is created with a satin milling machine, looks a bit coarser than a cross matt and makes the ring appear even more voluminous. Also with Satiniermatt it should be noted that over time the surface changes more and more to a polished look due to the signs of wear, but it is somewhat more stable than a cross matt due to the deeper millings. Due to the manufacturing process, this surface is only recommended on straight profiles. |

|

HedgehogSimilar to a coarse matt finish: Evenly matt ring surface, which is evenly littered with coarser "dots" and thus results in a lively, "hedgehog", matt surface. Popular, somewhat more unusual alternative to sand or matt, as this surface is a little more resistant thanks to the use of a special diamond-tipped milling attachment. |

Galvanic surface treatment: rhodium platingDuring rhodium plating, a rhodium coating is applied over the alloy as a surface coating. Rhodium is characterized by high corrosion resistance and great abrasion resistance. With the galvanically applied bright white rhodium coating z. B. white gold lightened and silver jewelry protected against tarnishing. Rhodium plating is basically possible for almost all surface structures. |

Are you a specialist dealer and the surface you are looking for is not there?

We also manufacture special surfaces on request, please contact us .

Retailer information

Your advantages as a Merkle partner:

- Special surfaces are also possible

- Orders from one piece

- Dimensions and quality "Made in Germany"

- Fast delivery times with the highest quality standards

- Would you like to find out more? Please do not hesitate to contact us!