Production of individual rings

The HCF Merkle company in Hamburg has been making wedding rings and other pieces of jewelry for jewelers and goldsmiths from all over Europe since 1853. We use our many years of experience and loving craftsmanship together with the latest technology to meet even the most individual customer requests.

Merkle not only manufactures ring profiles that are used by specialist retailers for further processing, but also offers you the whole world of wedding rings and jewelry manufacture, including completely ready-to-ship wedding rings or other jewelry rings, with or without stones in a wide variety of surfaces – with or without joints .

Laser and facsimile engravings are also no problem for us: all imaginable symbols, handwriting and even fingerprints can be engraved inside and outside. At Merkle, there are no limits to your creativity as a customer.

Our wedding rings are produced using the latest jewelry manufacturing technology. But machines alone do not make our rings. Only the craftsmanship of our long-term employees in the goldsmith’s, the gemstone setting or the polishing shop give each wedding ring its individuality and thus its very own soul. We take particular care to adhere to our strict quality criteria and to check ourselves regularly.

Blank ring production

Most of the raw rings we use, from which the actual rings are later turned or milled, we manufacture ourselves. We do this through the direct use of precious metal tubes, which we first saw and then pull, roll or twist to the right size. This makes us very flexible and is one of the reasons why Merkle has exceptionally fast delivery times, which long-term customers appreciate very much.

Turning and milling

With the help of the high-gloss internal and external machining of our Benzinger lathes or the 5-axis controlled high-precision machine 5 @ work from Benzinger, the ring blanks are brought into the desired shape and the wedding ring is given its individual profile. Depending on the width and height of the ring, we make sure that the inner curve – also called crowning – is always designed to be optimally comfortable to wear.

Multi-colored wedding rings, bicolor or tricolor, are also processed here. We only sinter these rings. This means that they are heated to just before the melting point and then pressed together under enormous pressure, so that a seamless connection of the different materials is created.

Surface treatment

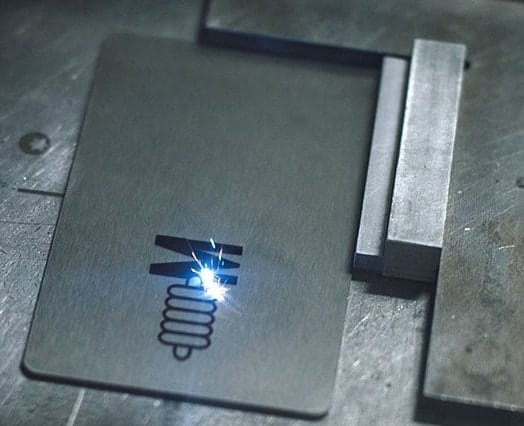

If the ring is to have a unique pattern (grooves, joints or depressions), this is achieved by laser or milling. Depending on the model and type of surface, milling is carried out fully automatically on the 5 @ work milling machine or by manual operation of a machine (e.g. diamond cut).

Setting precious stones

With wedding rings and engagement rings, there are a variety of types of barrel with which gemstones are firmly anchored in the ring. To this day, the setting is mostly carried out carefully and precisely by hand. Our experienced gem setters set the gemstones in any desired type and position.

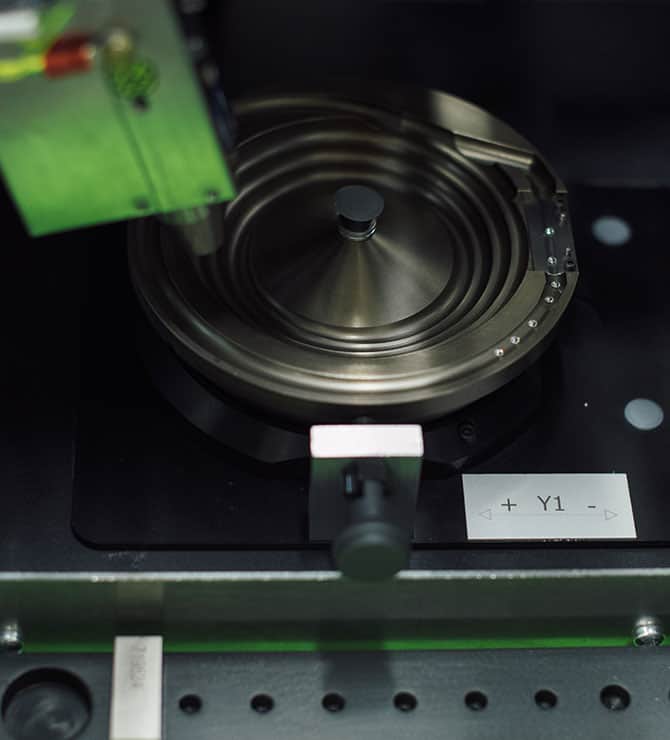

Fully automated gem setting

At Merkle, however, we also offer fully automated gem setting. The stones are then measured using the Four C machine. Here, stones are measured automatically and individually and stored in classified collection bins and magazines. The measurement data collected for each stone can then be automatically passed on to the milling machines, where the right seat for the setting is worked out for each stone.

Goldsmiths

The production of rings is still partly manual work: Almost every one of our Merkle rings goes through the hands of a goldsmith, who then carries out fine work such as filing, soldering or lasers and other types of surface refinements such as hammer blows or special matting. Craftsmanship can be experienced here.

Polishing shop

Our polishers then give the wedding rings their final surface and thus their individual appearance. Polishing requires a sure instinct and a lot of experience. Depending on the wedding ring model and surface combination, our employees sometimes apply different ring surfaces to a wedding ring. This is an art in itself!

Engraving

In the last step on the way to the finished Merkle ring, individual customer requests are engraved into the ring surface with our three lasers or our diamond engraving machine. These include: Fonts of all kinds in all common computer fonts, facsimile engravings, such as symbols, coats of arms or logos according to your individual template or your fingerprints.

Like our rings, our engravings last a lifetime.

Retailer info

- 98% of our customers are satisfied or very satisfied

- High quality production of single and multi-colored wedding rings

- State-of-the-art technology combined with many years of experience

- Very high quality demands on ourselves

- We stand for reliability, high quality and craftsmanship

- Personal contact

- Would you like to find out more? Please do not hesitate to contact us!