One of the whitest alloys with one of the highest proportions of precious metals in our range: PlatinumGold.

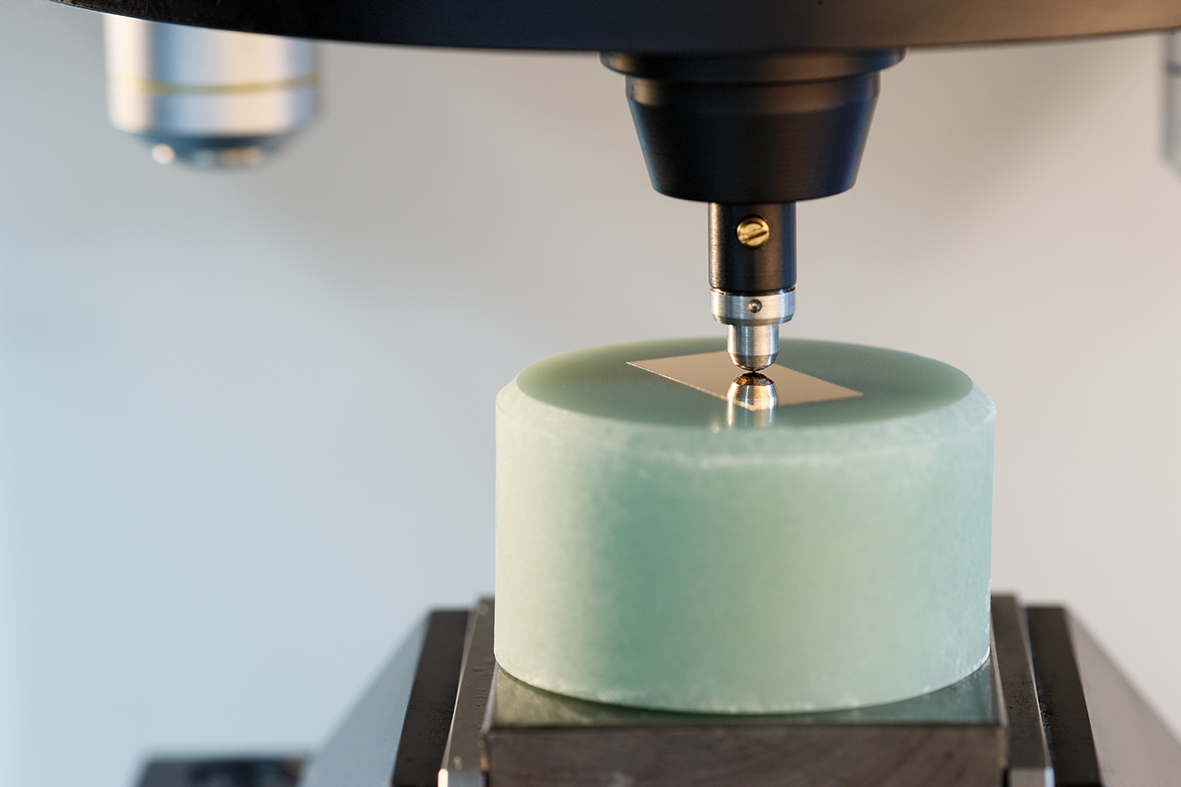

97,5% precious metal quantity PlatinGold

Even regular platinum 950 is one of the highest quality alloys, which already has very good properties for jewelry production with a 95% platinum content.

In the case of platinum gold, this high precious metal content is increased even further, so that a total precious metal content of 975‰ is achieved. The patented composition (patent number DE102012007299A1) contains 950‰ of the precious metal platinum, the precious metal gold with 15‰ and the precious metal ruthenium with 10‰.

The recipe completely dispenses with potentially allergy-causing elements such as copper, gallium or even cobalt.

| Property | PlatinumGold 950 |

| Hardness | 160 – 170 HV |

| Curing | No embrittlement |

| Grain size | approx. 200 μm |

| Melting interval | 1,640 – 1680 °C |

| Alloying element(s) | Indium (complete omission of critical elements) |

Excellent material properties and workability

By dispensing with reactive elements such as tungsten or gallium, PlatinGold is more forgiving than conventional alloys, even when processed by a goldsmith.

PlatinGold can be easily soldered and welded because the undesirable oxidation that occurs with other platinum alloys is prevented by largely dispensing with additional alloying elements.

With a hardness of 165-170HV (Vickers hardness), PlatinGold has a good basic hardness even in the unhardened state. Cold forming (as used in wedding ring production) increases the hardness to around 270HV with seventy percent forming. PlatinGold shows no undesirable signs of hardening; Soft-annealed, the possible elongation is more than thirty percent and even after seventy percent cold working, the residual elongation capacity is more than 5 percent.

The bright white color of PlatinGold is particularly beautiful, especially in connection with colored stones or diamonds, which can be set particularly securely in this material. PlatinGold is not magnetic.

Super white color (Grade 1 Premium White) – permanent

So far, PlatinGold has mainly been used for luxury watches (e.g. the Omega Seamaster 300) and by some French luxury jewelry brands, who also value the alloy for its scratch and wear resistance.

With PlatinGold, there is no need for the rhodium plating that is customary with white gold in order to achieve a particularly white, chrome-colored surface. With an electronegativity of 2.28 on the Pauling scale, the precious metal platinum is one of the most corrosion-resistant and inert elements. The PlatinGold surface does not oxidize and does not accumulate other substances from the environment. As a result, this material is also suitable for sensitive wearers: inside and allergy sufferers: inside.

The yellowness index of PlatinGold is 10 (comparing platinum-copper, for example, 13), a lower value stands for a more brilliant white.

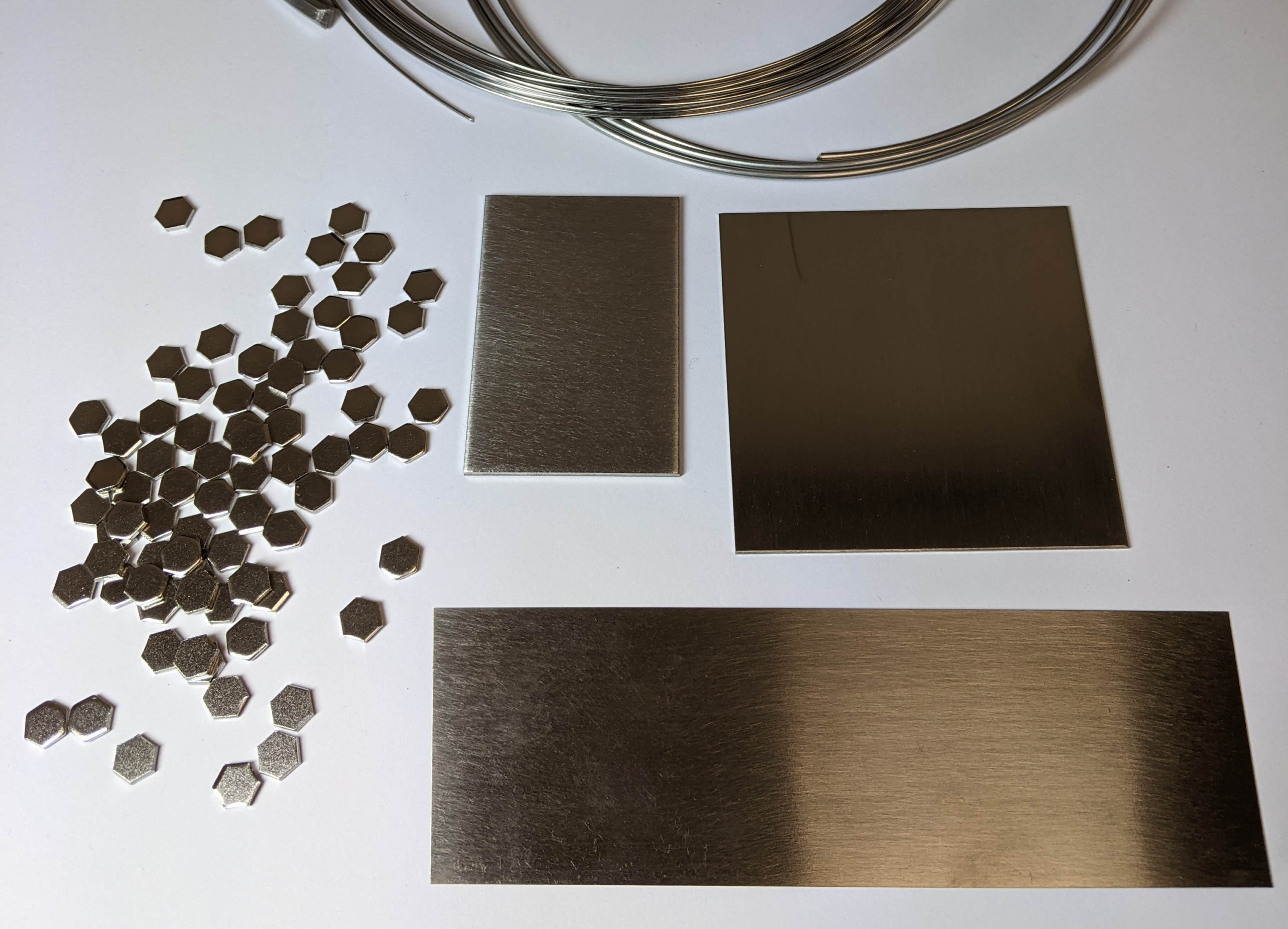

Semi-finished product range, solders and cast cubes available from Merkle

Matching the quickly available blanks, profile rings or rings that are set with stones, Merkle also offers a range of semi-finished products that can usually be delivered within one day or can be delivered together with your ring order.

The semi-finished products that can be delivered immediately include sheet metal with a material thickness of 1mm and 2mm, octagonal wire rod with an edge length of 5.3mm, and wire with a diameter of 1mm and 2mm.

For those who are able to cast platinum, we also offer cast cubes, with PlatinGold these are octagonal cast plates for further processing.

Furthermore, we offer a large selection of suitable solders, these are supplied as 0.3mm thick sheet metal, depending on the application, the following solders are available:

| Platinum solder in sheet form (0.3mm thickness) |

Working temperature | Melting Interval |

| Soft | 950 °C | 870 – 940 °C |

| Medium | 1,080 °C | 1,005 – 1,055 °C |

| Hard | 1,235 °C | 1.170 – 1.1230 °C |

| Extra Hard | 1,250°C | 1,210 – 1,280 °C |

Sustainability and recycling origin

The processed gold and platinum comes exclusively from recycling (secondary sources). The PlatinGold supplier has undertaken to observe the guidelines developed by the OECD for the responsible use of precious metals, but is also RJC (Responsible Jewelery Council) certified. In addition, the supplier is a member of Urban Mining e.V., this association regards cities and settlements as raw material mines in which valuable resources of all kinds are tied up for different lengths of time, but are then released and usable again.

Deleted: Due to the limited availability in the deposits, the recycling of precious metals will continue to increase worldwide in the next few years, precisely because there are still challenges in the area of human rights and working conditions with conventional (primary) mining and primary mining alongside the serious intervention in the environment also has a burdening CO² balance.

The amount of platinum mined worldwide to date is around 16,000 tons, of which around 12,000 tons are in circulation. If you imagine the entire quantity mined worldwide to date as a cube, the edge length of this cuboid is only 9 meters.

Or to put it another way: The Elbphilharmonie in Hamburg weighs around 13 times the platinum deposits in the world. If you wanted to build a massive replica of the Elbphilharmonie out of platinum, you would need platinum deposits from around 900 planets “Earth”.

Due to these limited quantities, there is a need to recycle as much of the platinum as possible.